NET SHAPE COMPOSITE

Manufacturing Solutions

Radius Engineering provides engineering services for all aspects of advanced composite structure design and fabrication. Our process and engineering services are internationally recognized and acclaimed.

Focus

We focus on Net-Shape and Out of Autoclave (OOA) composites using Closed-Mold techniques. We utilize the following materials and methods:

- Resin Transfer Molding (RTM)

- Same Qualified Resin Transfer Molding (SQRTM)

- Internal Pressure Molding (IPM)

- Automated or hand-laid prepreg preform technology

- Tradition and 3D woven, braided or stitched dry preforms

- Co-cured prepreg and dry preform structures

- Co-bonded metallic fitting integration

Technology Transfer

We develop and transfer the composite manufacturing processing technology to our customers, and provide them with continued support during the production life-cycle. This includes on-site part fabrication and equipment use training.

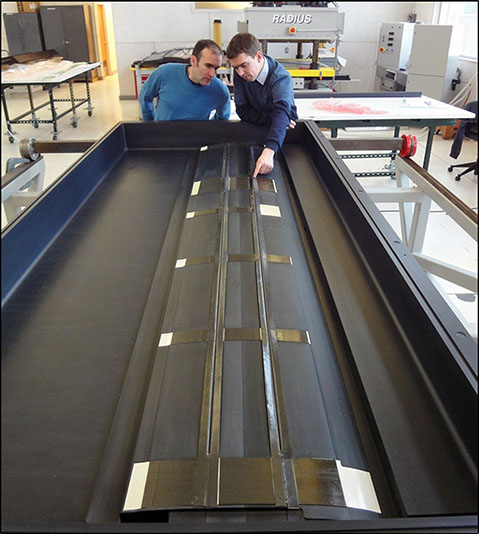

Our Development and Tooling engineers are skilled in designing metallic closed mold tooling. We provide hard-anodized aluminum and steel tooling for most applicationss.

Experience

Precision machined tooling systems for High Performance composite applications.

- Complete product integration from concept to first article fabrication.

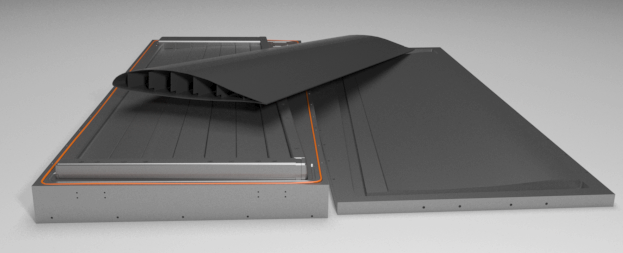

- Closed mold tooling allows for the fabrication of unitized Net-Shape structures.

- Demonstrated design and fabrication of closed molds large tools as large as 264in x 72in x 17in (6.7m x 1.8m x 0.23m).

Cornerstone

Net-shape Tooling Design and Supply is a Cornerstone of Radius.

- Tooling is a core competency of Radius technology and has been since the company’s founding.

- 20 years of RTM Tooling, significantly longer than anyone else in industry.

- Exclusive focus on net-shape, closed mold tooling.

Design & Build

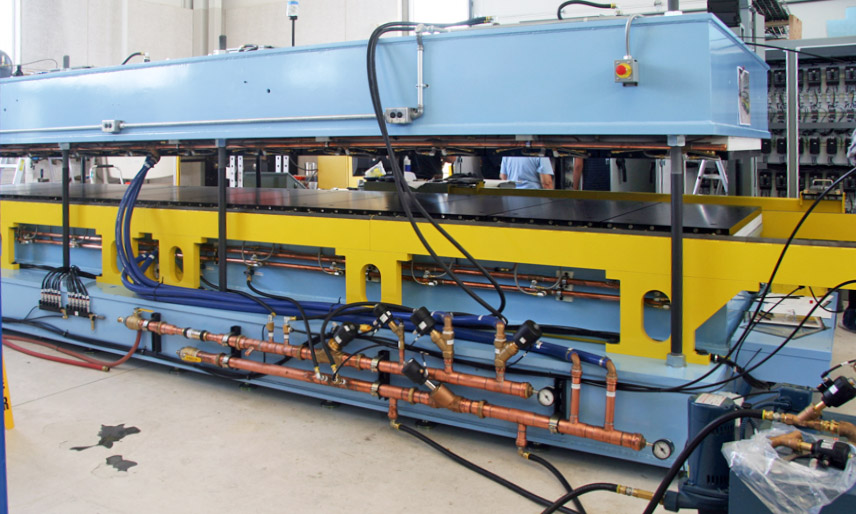

Radius Engineering designs and builds composite manufacturing workcells to the precise specifications required by our customers for successful composite manufacturing. We provide ongoing training, service and technical support that facilitates continuous process improvement and a reliable supply of spare parts.

Workcell Products

- Pneumatic Presses

- Up to 800° F (425° C)

- Composite Forming Equipment

- Control Systems

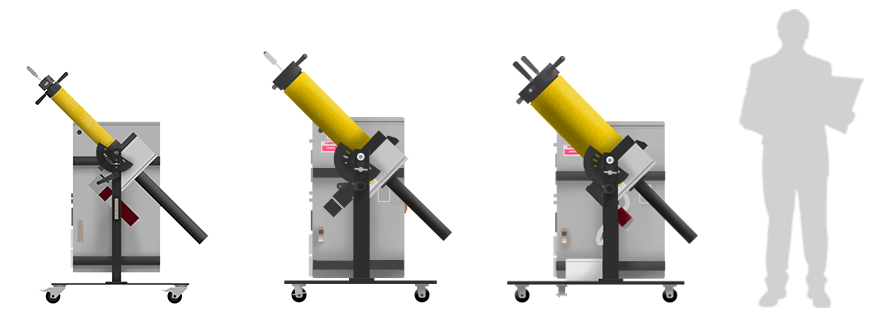

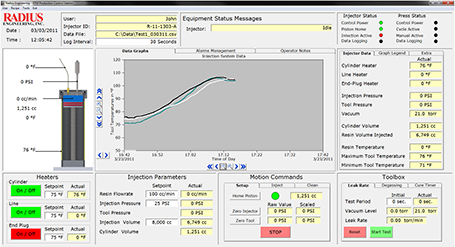

Radius Engineering designs and manufactures state of the art resin injection systems that are engineered to lead the industry in Resin Transfer Molding (RTM) and Same Qualified Resin Transfer Molding (SQRTM). Radius' injection systems are designed to inject single component or pre-mixed multi-component resin systems.

Custom injection systems are available for your applications. Contact Radius Engineering for further information.

Radius' 1K and Multi+ 2K Injection Systems use a servo-driven piston and hydrostatic pressure to govern resin flow and internal tool pressure. The Multi+ 2K system can also dispense pre-mixed 1K resin like our industry reference 1k system.

Total Process Control

- Temperature

- Pressure

- Flow Rate

- Up to 600° F (315° C)

- Up to 435 psi (30 bars)

Critical resin injection parameters including resin pressure, temperature and flow rate are controlled and logged to a data file via custom Supervisory Control and Data Acquisition software developed by Radius Engineering.